Quality wood products from around the world.

InterGlobal Forest Overview

NEATFLEX™ has a 4mm (5/32") S - Grade Birch plywood face bonded to a 15mm MDF Lite platform. It comes in 1220 (48") x 2440mm (96") Cross Cut / Cross Grain sheets with un-grooved border edges, approximately 40mm wide on the two edges running parallel with the grooves.

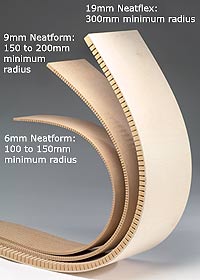

The typical minimum bending radius obtainable using NEATFLEX™ is 300 mm (12"). If a tighter radius is required it is best to use NEATFORM™ Bendy MDF which has a minimum bending radius of 150mm (6"). Bending capabilities of NEATFORM™ and NEATFLEX™ may vary with the moisture content and temperature and, because it is manufactured from natural raw materials, it may vary slightly from one batch to another.

NEATFLEX™ is not made from fire resistant MDF nor is it recommended for wet applications.

NEATFLEX™ should be acclimatized the same as the surfacing material, adhesives, paints or lacquers to be used. If available, refer to the fabrication guidelines for the surfacing material, adhesives, paints or lacquer.

| European / Metric Panel Notation | ||||

| Panel Size | Thickness | Wt./Sheet | Wt./Sq.M | Pallet Quantity |

| 1220 x 2440 mm Cross Cut | 19mm | 23 kg | 7.72 kg | 20 panels |

| North American Panel Notation | ||||

| Panel Size | Thickness | Wt./Sheet | Wt./Sq.ft | Pallet Quantity |

| 96" x 48" Cross Cut | 3/4" | 51 lbs | 1.63 lbs | 20 panels |

The bending characteristics of NEATFLEX™ and other materials such as laminate vary with temperature. Care must be taken, especially in cool conditions, that the materials do not become too brittle to work with.

g

gBecause of the wood grain face, laying up with veneer prior to bending is not recommended.

Care should be taken when handling NEATFLEX™. The size, weight and flexibility of a full sheet will generally require two people to ensure that the material is not over-flexed or broken.

NEATFLEX™ should be stored flat in such a way that both surfaces are protected. Store in a dry area and avoid direct contact with the floor.

When working with any timber based product including MDF it is important to take health and safety seriously. Protective goggles and a dust mask are essential. MDF must be cut in a well-ventilated area and all machining tools should be fitted with dust collection systems.